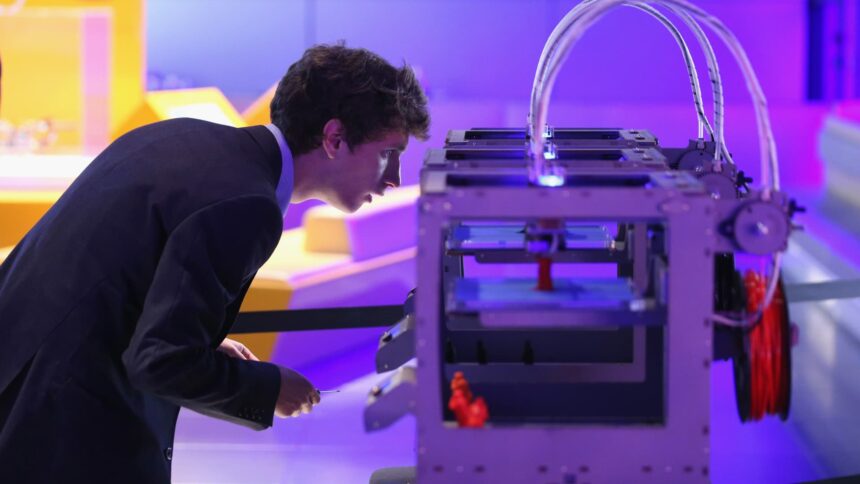

A new era of “microfactories” of 3D printing helps to transform the plastics of waste into “highly competitive” products adapted to use in the construction industry, according to Veena Sahajwalla, professor and founding director of the Center for Research and Technology of sustainable materials of the UNSW.

Addressing CNBC Mandy Drury at Sydney Innovation Summit by Schneider Electric on Monday in Australia, Sahajwalla said that manufacturers had to direct their reflection on sustainability towards profitability.

“It’s not about saying, well I do it because it’s green. In fact, it should be the last thing. The first thing must be profitability, does it work? Is that good performance?” She said.

This thought pushed Smart to build plastic filaments made from 100% waste plastics from “all kinds of old printers”.

They are built in hyper-localized and highly automated “microfactories” to produce personalized products.

“If that [waste-made plastic] Can now be introduced into a 3D printer, can you really print a whole range of products? “She said.

One of these already manufactured products are “pliers” – or blocks – used in construction and construction projects.

“Imagine all the construction and construction projects where you need plants and imagine if you had to wait a long time to stock up on these parts and components,” said Sahajwalla.

Large expenses on plants during construction projects mean that companies often buy them used.

The 3D printed alternative of Smart, integrated in microfactory in Sydney using plastic filaments made from older plastic waste, could ultimately reduce costs, says Sahajwalla.

“You could literally speak to your local microfactory and say, can I make a comparative price and the right type of performance?”

“This is where microfactoric technologies have intervened. To really fill the gap between what is considered to be waste on the one hand and on the other hand, do something high, high technology and to fulfill the gap.”

Hydrogen revolution?

Autonomous trucks and buses, powered by a hydrogen -based energy, are about to take the roads, thanks to a technology still to its stammerings.

Scott Brown, director general of Pure Hydrogen, told CNBC that his company now had a garbage truck powered by hydrogen in the city of Adelaide emitting “no diesel pollution, which can be detrimental to your health if you breathe it”, as well as less sound pollution of sound pollution during morning deadlines.

He predicts a drop in fuel cell prices during the 10 to 15 year olds.

Car manufacturers Honda,, Toyota And Hyundai have already adopted more fuel cell engineering.

Fuel batteries refer to the use of hydrogen or other fuels to produce clean electricity.

“There is not a lot of equipment involved. It looks like a PC and you put it – in our case – a truck or a bus,” said Brown.

Due to its increasingly profitable production, the prices of fuel cells have dropped “around 50% in the past three years,” he added.

Brown predicts that prices for clean energy battery cells will become “considerably” during the next decade, as Chinese companies adopt more vehicles powered by hydrogen.

According to Figures published by the South Korean analyst research group SME In November, sales of hydrogen commercial vehicles in China have more purchases worldwide.